This is innovation.

Nature is better than us at everything

Back from vacation with the wonderful, humbling reminder baked into my brain that nature creates art perfectly, effortlessly, and at such extremes of scale that we are simply horrible imitators.

Time for vacation and looking ahead

I’m finally able to have enough time to take a vacation from work. This is my first real vacation in 2-1/2 years! I get to travel a fair amount with work (not that I love flying) so I’ve been able to get out of town more than my wife. So I’m taking her to a town I’ve been 4-5 times this summer — Seattle, WA. Land of not 110-degree days. Thankfully!

Between not printing last weekend and being gone the next two, it will be almost a month between my last print and next. Weird.

But… I already have plans for the next item — the results of a several week concept I’ve been working on in order to write both a blog post for work, as well as prepare a deck for trying to speak at conferences. I was going to apply to speak at the 3D printing conference in the Netherlands in October, but the timing was bad and I wasn’t sure I was going to be prepared enough. I’ll probably just get up on a soap box and espouse the virtues of home fabrication from the street corner.

I also have plans to switch to the MK7 extruder (in dual mode, of course) from MakerBot so as to use the water soluble PVA for support structures instead of the ABS; most everything I design needs support and going this route should make it easier to get cleaner prints (also due to the 1.75mm filament change). But first I have to use up all the 3mm filament I’ve got! That might also give MBI enough time to get 1.75mm PVA in stock. 😉

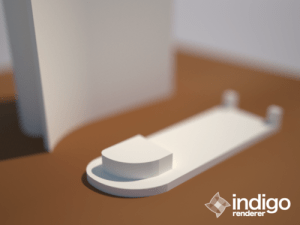

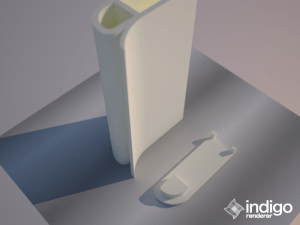

I leave you with some images from a fantastic rendering plug-in for SketchUp (and almost every other 3D software package) called Indigo. I used to use Indigo when it was alpha/beta and free to the public. It is certainly worth it as a paid product if you are using it professionally; I can’t afford the licensing to only use it here or there. The 30 day trial is enough to play with and see how far it has come since I last touched it (2007?). Good stuff. I didn’t let the images render to “completion”, but the state they are in was good enough for me to see it still rocks. I also didn’t work on any of the textures to try to make it look like printed plastic; this wouldn’t be difficult, but I’m just messing around.

The MothBees Have Come!

After being very happy with my MothBee printing and finishing experiment, I decided to send the file to Shapeways to see how materials that I cannot print would look. After placing an order for MothBee in black glossy glass, white matte glass, antique shiny bronze, and stainless steel, Shapeways said I would be getting the objects the week of October 3rd. Perfect timing as I am going on vacation next week and would come home just in time to receive the package. Much to my surprise and delight, a ring of the doorbell this evening led me to find a box resting against the door with all my objects!

Just because you can, doesn’t mean you should – Volume 1

So last weekend I did actually print something, despite the lack of post on this site. It was the first (of I’m sure many) of my “good print, but really?” moments. And of course it was super mundane.

[ UPDATE ] Added photos with ruler (in inches) since I forgot them earlier. 🙂

This blog has its own domain now

I decided I should go ahead and buy the domain MyPlasticFuture.com before some sleazy domain-squatter does. It also makes it easier to type as most people can’t get my last name right (a common problem).

So – www.myplasticfuture.com will now bring you here!

I’ll leave you with a picture of my first two prints, and the item they replaced:

We’ve come so far so quickly little MakerBot. *sniff*

A Long Weekend Full of Wonderful Things

Ten. That’s how many completed print jobs I managed over the long holiday weekend. Yes, there was also one aborted print. Ten is fantastic given my previous concerns about over-heating, bad electricity, inconsistent temperature settings, and so forth. And the outside temperature was below 100-degrees for the first time in seemingly years. This really was a good weekend for printing. Of course, just a few miles away, Texas burns; not all is cake and ice cream.

Blame it on the heat, yeah, yeah…

So I discovered that apparently it wasn’t the heat that made my Thing-o-Matic freak out! (Which, really, at 109 degrees that day was the first thing I went to, especially given the outrageous heat coming off my Macbook Air).

Shower Razor Holder (Another Mundane Thing)

Just prior to slamming the extruder into my heated build platform (HBP), I was going to print a razor holder that would hang on the side of the wire baskets in the shower. However, after that horrible (at least mentally) event, I switched to something smaller (the shelf clip) so as to not waste plastic. The wait paid off.

Alles klar, Herr MakerBot?

After leaving yesterday with a serious case of “grinding noises” and small bits of plastic filament in the extruder gear, I was anxious to return to the studio today after work and do a check-up on my Thing-o-Matic. I naturally worry that I destroyed it already; nothing new, it’s my way to worry incessantly and imagine things at their extreme.

I discovered that the front lexan plate on the extruder head was incredibly loose! (In hindsight, I really should have done a more thorough check when I opened the box instead of a cursory one). A quick tightening of all of the bolts, some mouth-air blown into the top to expel little plastic bits, a good oiling of all of the axis rods, and a cleaning of the kapton tape and all is good. A test extrusion worked without a hitch and we should be good to go for the next print (which sadly probably won’t be until next weekend due to a busy week ahead at work).

At least I can sleep tonight.